|

|

| VIBRATORY

GRINDING MACHINES |

| |

| automatic

material-selecting finishing machines: |

|

The grinding

basin (drum) to be in screw shape. |

|

As grinding

process is completed, screening process would proceed automatically;

thus labour effort can be saved. |

|

Selection of

processed materials: As finishing or polishing is completed, turn

down the selection valve. The grinding stone will fall down into the

trough. Material after separation by screening mesh, will flow into

selection trough. |

|

Selection of

processed material will take about five minutes per basin (drum). |

|

| |

|

|

|

|

| TYPE¡G

|

| KO |

KUS |

| model |

KO-30 |

KO-100 |

KO-200 |

KO-300 |

KO-300(¿û¯]) |

| capacity |

30 |

100 |

200 |

300 |

300 |

| diameter |

550£r |

880£r |

1080£r |

1350£r |

1350£r |

| height |

700 |

1000 |

1000 |

1100 |

1100 |

| power |

0.75HP |

|

|

|

|

| amplidude |

3~6m/m |

3~6m/m |

3~6m/m |

3~6m/m |

3~6m/m |

|

|

|

|

|

|

|

| weight (kg) |

100 |

350 |

450 |

550 |

550 |

|

| model |

KUS-100 |

KUS-200 |

KUS-300 |

| capacity |

100 |

200 |

300 |

| diameter |

1000£r |

1150£r |

1300£r |

| height |

1000 |

1030 |

1200 |

| power |

|

|

|

| amplidude |

3~6m/m |

3~6m/m |

3~6m/m |

|

|

|

|

|

| weight (kg) |

400 |

500 |

600 |

|

| |

|

| KU |

| model |

KU-20 |

KU-50 |

KU-150 |

KU-250 |

KU-350 |

KU-500 |

KU-600 |

KU-800 |

KU-1000 |

| capacity |

20 |

50 |

150 |

250 |

350 |

500 |

600 |

800 |

1000 |

| diameter |

440£r |

720£r |

800£r |

1080£r |

1300£r |

1460£r |

1624£r |

1920£r |

1920£r |

| height |

650 |

880 |

1000 |

1000 |

1100 |

1100 |

1100 |

1100 |

1100 |

| power |

0.5HP |

1HP |

|

|

|

|

|

|

|

| amplidude |

3~6m/m |

3~6m/m |

3~6m/m |

3~6m/m |

3~6m/m |

3~6m/m |

3~6m/m |

3~6m/m |

3~6m/m |

|

|

|

|

|

|

|

|

|

|

|

| weight (kg) |

80 |

200 |

350 |

450 |

550 |

600 |

650 |

700 |

800 |

|

|

| |

|

| |

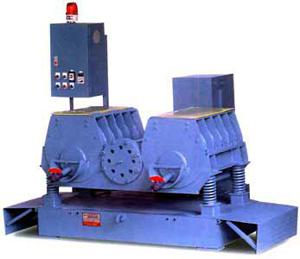

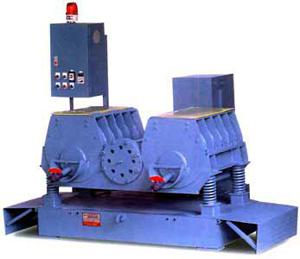

| horizontal

grinding machine |

centrifugal

grinder |

|

|

|

|

|

| The design

of this machine is based on the dualistic vibration principle.

The running speed is controlled by a stepless control. The inner

side of the grinding drum is coatsd with PU or rubber. And the

round grinding drum can be specially designed into the rectangular

form according to the length of the work piece. The purpose

of this machine is to remove burr, prick and coarse surface,

achieving the grinding effect. |

| ¡°The

size of the drum can be designed in accardance with the users'

requirement. |

| model |

KRH |

| capacity |

55X2 |

| diameter |

350£rX580H |

| R/M |

1000~2000 |

| power |

5HP |

| amplidude |

0~4m/m |

| size |

1500X1400X1000 |

| weight |

400kg |

|

|

| This design

of this grinder is for applying to the harder metal productions

for removing the oxidated film, burr and sharp poing. The other

feature is that it is able to automatically unload the finished

products and to tilt itself to one side for easy feeding. Ther

operation principle is by using a high speed rotation bottom

plate for generating a centrifugal force which can push the

working items and the grinding stone to do a friction against

the grinding sump causing a screw rolling whirlpool. Thus it

achieves the grinding function. |

| model |

KRF-45 |

KRF-200 |

| capacity |

45 |

200 |

| diameter |

430£rX310H |

820£rX450H |

| R/M |

200R.P.M. |

30~130R.P.M. |

| power |

2HP.1/8HP |

7 1/2HP |

| size |

960X960X1000H |

2000X1100X1200H |

| weight |

300kg |

1100kg |

|

|

|

| |

|

|

|

|

|

|